Panel Filter:

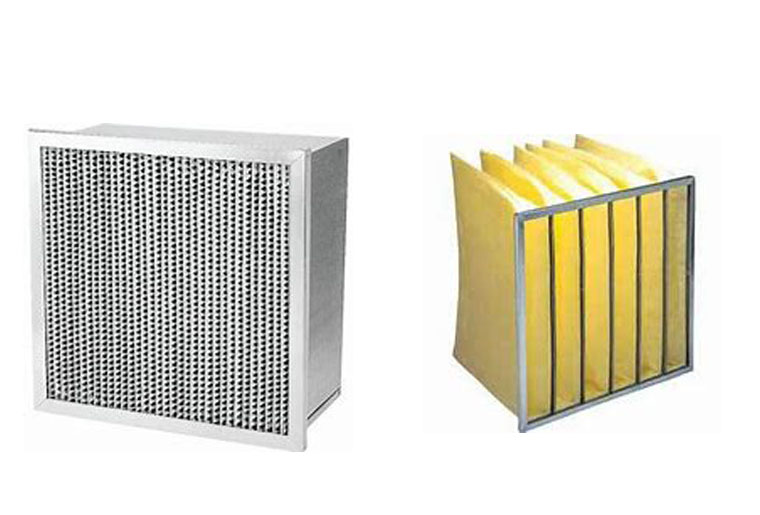

A panel filter is a type of air filter commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems and industrial applications to remove airborne particles from the air. It is called a panel filter because it is typically a flat or pleated filter contained within a sturdy frame or panel.

Panel filters are available in various sizes and filtration efficiencies, allowing them to be used in different applications. They are often made of synthetic fibers or pleated paper media, which effectively capture dust, pollen, mold spores, and other airborne contaminants as air passes through the filter. The frame of the panel filter is usually made of metal or plastic and provides structural support to the filter media.

These filters are relatively easy to install and replace, as they can be simply inserted into the filter housing or frame. Regular maintenance and replacement of panel filters are important to ensure efficient air filtration and prevent clogging, which can lead to decreased airflow and strain on the HVAC system.

HEPA Filter:

HEPA (High-Efficiency Particulate Air) filters are among the most efficient air filters available on the market. They are designed to remove extremely small particles, including dust, pollen, pet dander, bacteria, and even some viruses from the air. HEPA filters are commonly used in environments where clean and pure air is crucial, such as hospitals, laboratories, cleanrooms, and in certain industrial processes.

To be classified as a true HEPA filter, it must meet stringent standards set by regulatory agencies. These standards require the filter to remove at least 99.97% of particles that are 0.3 micrometers in diameter. HEPA filters achieve this high level of efficiency through a dense arrangement of fine fibers or a combination of fibers and other mechanisms like electrostatic charges.

HEPA filters are typically made of fiberglass or other synthetic materials, and they are constructed in a pleated or deep-bed configuration to maximize the surface area and filtration capacity. Due to their high efficiency, HEPA filters are commonly used in conjunction with pre-filters or in multi-stage filtration systems to prolong their lifespan and reduce maintenance frequency.

Pocket Filter:

Pocket filters, also known as bag filters, are air filters that are used to remove larger particles from the air in HVAC systems and industrial applications. They are called pocket filters because they feature multiple pockets or bags within a filter frame or housing.

Pocket filters are usually made of synthetic fibers, which provide high dust-holding capacity and efficient filtration. The pockets or bags are stitched or ultrasonically sealed to the frame, creating individual filter compartments. This design allows for increased surface area and higher dust-holding capacity, leading to longer filter life and reduced pressure drop across the filter.

These filters are available in different filtration efficiencies, depending on the application requirements. They are commonly used in commercial and industrial environments where there are high levels of airborne particulates, such as manufacturing facilities, automotive paint booths, and data centers.

Pocket filters are relatively easy to install and replace, and they are often used as pre-filters in multi-stage filtration systems. Regular maintenance and periodic replacement of pocket filters are essential to ensure proper air quality, prevent excessive pressure drop, and maintain the efficiency of the HVAC system or industrial process.