A basket filter and strainer are commonly used filtration devices in various industries to remove solid particles and debris from liquids or gases. They are designed to capture and retain particles that can potentially damage equipment, hinder the flow, or compromise the quality of the fluid or gas being processed. Basket filters and strainers are efficient, reliable, and versatile solutions for a wide range of filtration applications.

The primary component of a basket filter and strainer is the filter element, which is typically a mesh or perforated basket-shaped structure. This basket is made of materials such as stainless steel, carbon steel, or other alloys, depending on the compatibility with the fluid or gas being filtered and the operating conditions.

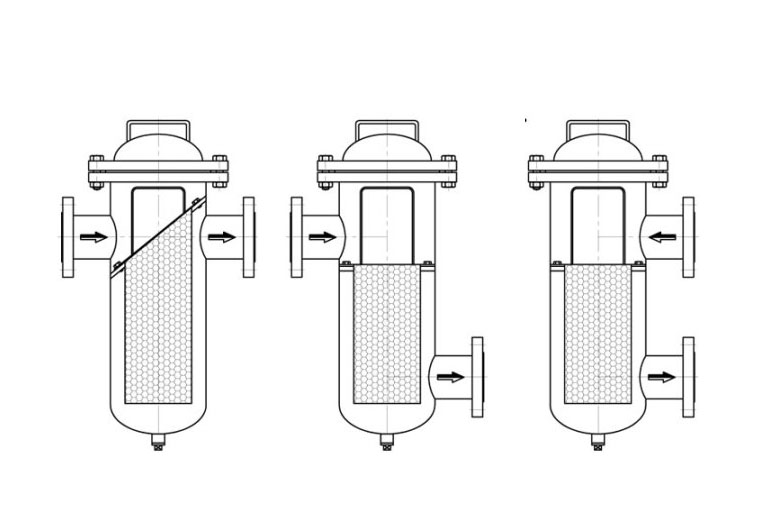

The basket filter and strainer housing enclose the filter element and provide a passage for the fluid or gas flow. The housing is usually constructed from sturdy materials to withstand the pressure, temperature, and corrosive nature of the process fluid. It includes inlet and outlet connections to allow the fluid or gas to enter the housing, pass through the filter element, and exit the system.

The operation of a basket filter and strainer is relatively straightforward. The fluid or gas flows into the housing, and the filter element captures the solid particles and debris as they pass through. The filtered fluid or gas then continues its flow through the outlet connection, while the captured contaminants are retained within the basket.

Basket filters and strainers are known for their high dirt-holding capacity and efficiency in removing particles of various sizes. The filter element's mesh or perforations are designed to trap particles while allowing the fluid or gas to pass through with minimal pressure drop. The size of the filter openings can be selected based on the desired filtration level, ranging from coarse to fine filtration.

One of the advantages of basket filters and strainers is their versatility in different applications. They can be used for both temporary and permanent filtration requirements, depending on the process needs. Basket filters and strainers are commonly employed in industries such as water treatment, oil and gas, chemical processing, food and beverage, pulp and paper, and pharmaceuticals.

Maintenance and cleaning of basket filters and strainers are relatively simple. When the filter element becomes clogged with particles, it can be removed from the housing for cleaning or replacement. Some basket filter and strainer designs feature a quick-opening mechanism, such as a hinged lid or bolted cover, to facilitate easy access to the filter element.

In summary, basket filters and strainers are effective filtration devices used to remove solid particles and debris from liquids or gases. They consist of a basket-shaped filter element enclosed within a housing. Basket filters and strainers offer high dirt-holding capacity, efficient particle retention, and versatility in various industrial applications. They help maintain the integrity of fluid or gas systems, protect equipment, and ensure the quality of the final product.